PF6400 is a 3.75-mil clear polyolefin film with a textured gloss finish that helps to eliminate glare and provides a very unique and pleasing viewing surface with a permanent adhesive system. This product is recommended as a short term (up to one year) overlaminate for indoor applications only. ASTM C1028 tested for slip resistance and therefore can also be used as a short term (1 month) interior Floor Graphic laminate.

You Must be Logged in to Add the Item to your Cart.

Description

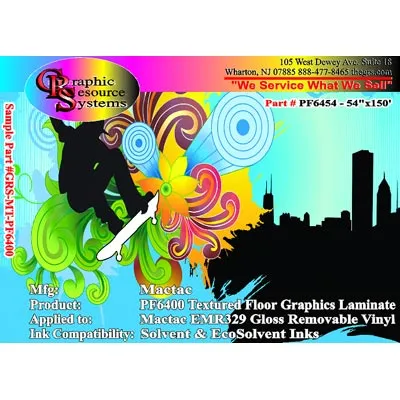

PermaFlex® PF6400 PERMACOLOR® The Permacolor system is a series of pressure sensitive products for mounting and overlaminating in the imaging industries. Pressure sensitive Permacolor provides fast, efficient processing through cold roll lamination techniques without the need for heat, drying or messy coating operations. PF6400 is a 3.75-mil clear polyolefin film with a textured gloss finish that helps to eliminate glare and provides a very unique and pleasing viewing surface with a permanent adhesive system. This product is recommended as a short term (up to one year) overlaminate for indoor applications only. PF6400 is ASTM C1028 tested for slip resistance and therefore can also be used as a short term (1 month) interior Floor Graphic laminate.

TYPICAL VALUES*

PHYSICAL PROPERTIES TEST METHOD

Thickness, inches (μm) ASTM D 645

Film plus adhesive 0.047 (120)

180° Peel Adhesion, lb. /in (N/25mm) PSTC - 1

Glass -20 min. 1.5 (6.5)

-24 hrs. 2.0 (8.7)

Static Coefficient of Friction (Slip Resistance) ASTM C 1028

OSHA recommendations:

Dry floors ≥ 0.5, Wet surfaces & Handicap accessible routes ≥0.6, Ramps ≥0.8

Dry Neolite 0.85

Leather 0.48

Rubber 0.66

Wet Neolite 0.66

Leather 0.66

Rubber 1.13

Temperature Range Guidelines

Application: 50°F to 100°F (10°C to 38°C)

End Use: -40° to 180°F (-30° to 82°C)

Adhesive pH 7.0 (Neutral) TAPPI-529

DURABILITY:

The indoor durability for this product is 1 month in floor graphic applications and 1 year for all other interior

vertical applications.

SHELF LIFE

Two years when stored between 60°F - 77°F (15°C - 25°C) and at 50% relative humidity or less.

Note: MACtac recommends that rolls be stored on end or suspended from the core.

IMPORTANT NOTICE: The information given and the recommendations made herein are based on our research and are believed to be accurate, but no guarantee of their accuracy or completeness is made. In every case, user shall determine before using any product in full scale production, or in any way, whether such product is suitable for user’s intended use for their particular purpose under their own operating conditions. User assumes all risk and liability whatsoever in connection with their use of any product. The products discussed herein are sold without any warranty as to merchantability or fitness for a particular purpose, or any other warranty, express or implied. No representative of ours has any authority to waive or change the foregoing provisions, and

no statement or recommendation not contained herein shall have any force of effect unless in an agreement signed by the officers of seller and manufacturer. Nothing contained herein shall be construed to imply the nonexistence of any relevant patents or to constitute a permission, inducement or recommendation to practice any invention covered by any patent without authority from the owner of the patent. The following is made in lieu of all warranties, express or implied: Seller’s and manufacturers’ only obligation shall be to replace or credit such quantity of the product proved to be defective at its discretion.

TM Trademark of Morgan Adhesives Company.

® Registered Trademark of Morgan Adhesives Company.

www.MACtac.com

CHEMICAL RESISTANCE:

Distilled Water (24 hr) No effect

Detergent (24hr) No Effect

10% HCL (10min) No effect

10% Ammonium Hydroxide (10min) No effect

Gasoline (1 hr) No effect

RECOMMENDATIONS FOR ROLLING AND SHIPPING LAMINATED IMAGES:

MACtac studies and field surveys with numerous customers using Permacolor® laminates in rolled-up graphic

applications, leads to the following recommendations for rolling and shipping laminated images:

1. Prior to rolling graphics:

a) A 2 - 4 hour wet-out period is strongly recommended for the adhesive system to build to ultimate

adhesion. This will significantly improve your success with rolled-up graphics.

b) This product can be used over UV inkjet and screen printed images. However, extra wet-out time is

required to reduce silvering and build bond prior to rolling.

2. For single-side laminated images:

a) Roll laminated side in for shipping and storage.

b) An inside roll diameter of 3 - 5 inches, minimum, is recommended for graphics with less than 10 mil

total graphic thickness (includes imaged media and Permacolor overlaminates).

c) For images with a total thickness of 10 mils or greater an inside roll diameter of 10 - 12 inches,

minimum, is recommended.

3. For images laminated on both front and back sides:

a) Roll images with the thicker laminate to the inside for shipping and storage. For example: if your

image has 5 or 10 mil polycarbonate or vinyl on the front and 15 mil Polycarbonate on the back (for

additional stiffness), roll the graphic with the 15 mil PermaFlex® side in.

b) All double laminated images should be rolled with an inside roll diameter of 10 - 12 inches minimum.

Remember that a larger inside diameter is better.

Please keep in mind that this is a recommendation, individual experience should not be discounted. We

recognize that different laminators and laminating methods may produce different results. The

recommendations above represent our experience as having the “greatest” success in the field.

1) The user is responsible for determining the product’s suitability, including adhesion and if

needed, removal characteristics when used in applications other than listed specifically in

this Performance Guide.

2) If there are any questions about applications, please contact your MACtac sales

representative to discuss your requirements for recommendations.

3) If this is a printed Performance Guide it is an uncontrolled document. Please check the

MACtac website for the latest, most up-to-date version.

• Values given are typical and are not necessarily for use in specification.

• Added Adhesive pH data

CALL 1-888-477-8465 for additional product information