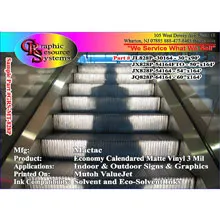

PRODUCT DESCRIPTION:

JT828P is a 3.1-mil matte white, soft-calendered PVC film designed for solvent-based ink jet printing. The product is coated on one side with a clear permanent, acrylic pressure sensitive adhesive and supplied with a 74# Kraft liner. JT828P is designed for general purpose indoor and short term outdoor advertising and promotion on flat or slightly curved surfaces

Description

PRODUCT DESCRIPTION:

JT828P is a 3.1-mil

matte white, soft-calendered PVC film designed for solvent-based ink jet printing. The product is coated on one side with a clear permanent, acrylic pressure sensitive adhesive and supplied with a 74# Kraft liner. JT828P is designed for general purpose indoor and short term outdoor advertising and promotion on flat or slightly curved surfaces.TYPICAL VALUES*

PHYSICAL PROPERTIES: TEST METHOD

Peel Adhesion,

lb. /in. (N/25mm) FTM - 1180° on Glass - 24 hr. 3.2 - 4.5 (14 - 20)

Quick Tack on SS,

lb. /in² (N/25mm) 2.1 - 3.2 (9 - 14) FTM - 9Dimensional Stability,

(%) FTM - 1448 hours @ 158°F max 1.0 10” x 10” Sample

bonded to aluminum.

Temperature Ranges,

Minimum Application: 40°F (+5°C)

End Use:

-40°F to 158°F (-20°C to 70°C)INTENDED FOR:

Wide format, eco-solvent, solvent-based and UV-cured inkjet printing. To achieve the best possible print quality, please make sure that the correct ICC profiles or printer settings are used. Profiles can be obtained from GRS. Printer and heater settings and ICC profiles can also be downloaded from some O.E.M. or software manufacturer’s websites.DURABILITY:

The indoor durability of this film is 5 - 6 years and the outdoor durability of the unprinted film is 2 years. Over lamination of the inkjet-printed material with Permacolor® overlaminates delays color fading that may occur over time. This color fading is mainly dependent upon the inks quality (see technical data sheets given by the ink manufacturers) and the pressure sensitive media being used.RECOMMENDATIONS:

Always test your combination of JT5000 products, inks and laminating films prior to commercial use.

Printing Conditions:

Print in conditioned pressroom at ±73°F (23°C) and 50% RH.

Laminating Conditions:

Ensure print is perfectly dry. Material should have 24 hr. drying time prior to lamination or transportation. If the printed graphic is likely to be exposed to corrosive liquids, smoke, fumes and highly polluted areas or there is a likelihood of scratching, it is highly recommended to laminate with

Permacolor LF3600

series (High Performance), PG7200 series (intermediate) or LF6500 seriesIMPORTANT NOTICE:

The information given and the recommendations made herein are based on our research and are believed to be accurate, but no guarantee of their accuracy or completeness is made. In every case, user shall determine before using any product in full scale production, or in any way, whether such product is suitable for user’s intended use for their particular purpose under their own operating conditions. User assumes all risk and liability whatsoever in connection with their use of any product. The products discussed herein are sold without any warranty as to merchantability or fitness for a particular purpose, or any other warranty, express or implied. No representative of ours has any authority to waive or change the foregoing provisions, and no statement or recommendation not contained herein shall have any force of effect unless in an agreement signed by the officers of seller and manufacturer. Nothing contained herein shall be construed to imply the nonexistence of any relevant patents or to constitute a permission, inducement or recommendation to practice any invention covered by any patent without authority from the owner of the patent. The following is made in lieu of all warranties, express or implied: Seller’s and manufacturer’s only obligation shall be to replace or credit such quantity of the product proved to be defective at its discretion.Transportation Conditions:

To allow for easy transportation, IMAGin JT5000 series can be rolled up, with the image out, with a minimum diameter of 6 inches (15cm). When the image is not protected by an overlaminate, make sure the print is completely dry and protected in a plastic bag. During transportation or storage, avoid exposing them to extreme temperature and humidity changes.