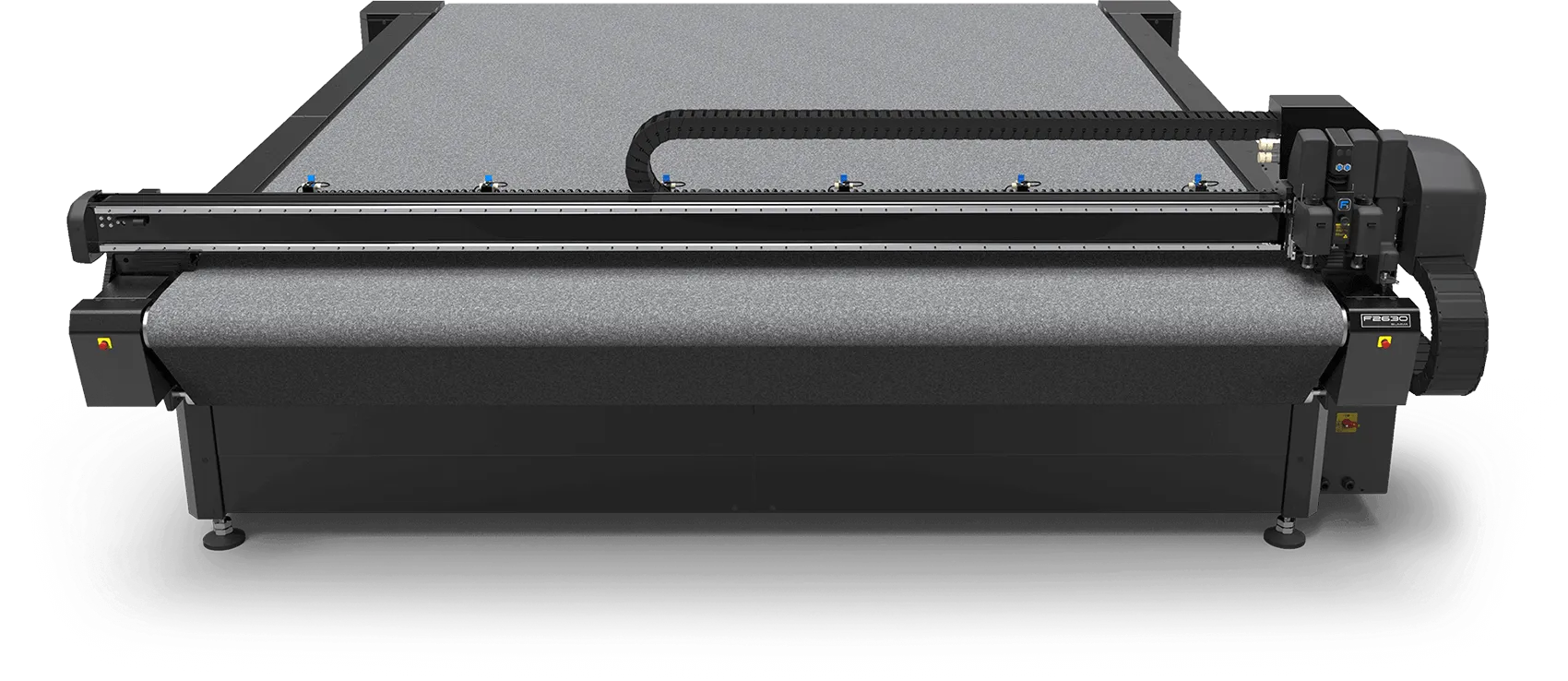

SUMMA F1612-41 Flatbed Cutting System Packed cutting table; work area 63x47" Includes: Vacuum Pack: Pump 1.75kW, sound absorber, switching valve conveyor system with 3 Pneumatic Media Clamps, and Roll-support Integrated Safety System Camera System Drag Module ADC Right & Left GoProduce STANDARD POWER REQUIREMENTS: 3 X 208V + N / 60Hz

Description

The most versatile flatbed cutting system ever

Summa’s Professional Flatbed Finishing System is an award-winning solution for producing innovative signage, displays, samples, packaging applications, and more. With an ever increasing arsenal of tools and optional add-ons, this is the breakthrough cutting solution you’ve been dreaming about.

Features

Industry-leading features and optional add-ons.

Multifunctional Head

The multifunctional head holds up to three modules at one time. The central unit houses a positioning laser and an integrated camera system for fast and accurate contour-cutting mark recognition.

Powerful Tangential Module

Offers a vertical force of 10 kg and corresponds to a wide range of matching tools. Each tool has a barcode identifier that ensures automatic recognition and parameter settings.

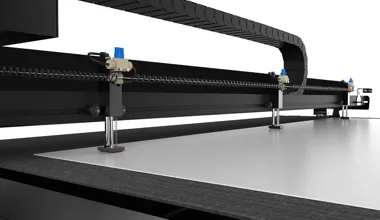

Media Advance Clamps

Pneumatically-driven media advance clamps hold the material down while pulling it forward in order to work continuously in panels or multiple jobs.

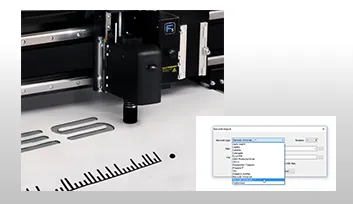

Barcode

The barcode workflow automatically identifies the job to obtain the necessary cutting data from the computer. Scanning the job happens automatically by the built-in camera of the Summa F Series system or by a hand scanner, depending on the selected workflow.

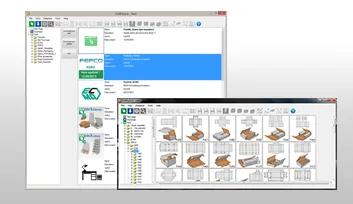

Axis Control Software

Axis Control software gives you full control over Summa's cutting table. The optimized design of the touch screen makes Axis Control the optimum interface for the machine operator. With the optional wireless controller, the operator is free to move around the table while changing basic settings.

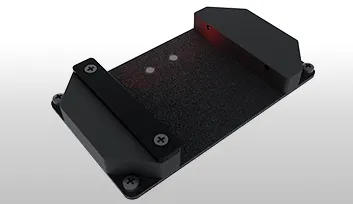

Safety Pack

The safety pack assures maximum security. A laser beam systems surrounds the table and controls the motion area. The unit can then work safely, using full speed while in production mode. When put into safety mode, the machine settings can be securely adjusted.

ADC

The Automated Depth Control (ADC) simplifies tool, knife or bit changes significantly. The ADC measures the tip of the knife or bit accurately and sets the down position of the tool to the level of the table. This ensures the best settings can always be used to get the most optimal cut quality.

PackLib

The PLM PackLib for Summa is a library of resizable standard packaging models. The most popular packaging standards FEFCO (corrugated cardboard) and ECMA (folding carton) are included. Also a few POS display designs and solid cardboards (furniture) designs are available.

Summa GoProduce

The user-friendly software GoProduce is part of Summa's GoSuite platform and is developed for the F Series' operator to handle jobs in a most straightforward and easy way. The software includes an extended range of important functionalities and a modern interface with improved navigation, which will enable users to find and operate functions as quickly and intuitively as possible.

Big, Bigger, Biggest

Available in six sizes to dramatically increase productivity.

Media Handling Has Never Been Easier

Pneumatic Media Advance Clamps

Pneumatically-driven media advance clamps hold the material down while pulling it forward in order to work continuously in panels or multiple jobs.

Vacuum Pump and Selector

The vacuum pump with sound absorber holds the material in place during the job while the selector adjusts the vacuum automatically to match the working area.

Conveyor System & Roll Support System

This conveyor system and media supply rollers allow the cutting and creasing of large lengths of flexible material to large production runs. The Roll Support System of the F2630 consists of two parts, so two smaller rolls can be loaded next to each other to maximize the workload of the machine. In combination with the Conveyor System and the media advanced clamps, the Roll Support System is ideal for processing roll material on all the Summa Flatbed Systems.