Graphic Finishing Products

663TH

theme600

theme600

Graphic Finishing Products

663TH

Production Top Heat Laminator

Gfp's most advanced laminator with "Smart Finishing Technology" for the demanding Wide Format Finishing Professional.

You Must be Logged in to Add the Item to your Cart.

Graphic Finishing Products 663TH

Top Heat Assist Laminator

FEATURING.......

Touchscreen User Interface

10” Tablet style LCD Display for user-friendly access to all functions

663TH Operational Displays

Microprocessor technology has expanded capabilities for Wide Format Finishing Professionals by increasing the efficiency, accuracy and reliability of finishing equipment. But that's not all. Now operators can program, monitor and display all machine functions and view operator tutorials through a powerful digital touchscreen Microcontroller. As a result, the Gfp 663TH expands operator expertise, productivity and accuracy providing consistent quality output and fewer production errors.

HOME SCREEN

displays machine status and links

operator to operational screens for

quick, efficient access to system setup

and adjustments.

SERVICE DISPLAYS

allow fine-tune adjustments and

calibrations to operating parameters to

increase efficiency and reduce waste.

ELECTRIC SERVO MOTOR ROLLER GAP DRIVE AND ENCODER

provides precise and repeatable

roller gap position to improve

accuracy and efficiency.

HELP TUTORIALS

are visual guides that improve

comprehension and retention

enhancing employee productivity,

proficiency, and confidence.

DIGITAL ROLLER PRESSURE DISPLAY

provides easy reference and adjustment

for fast, repeatable roller pressure to

ensure flat, quality output.

663TH Built-in Professional Features

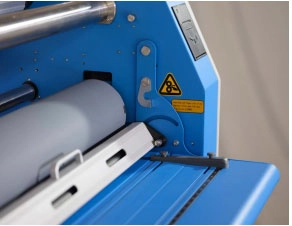

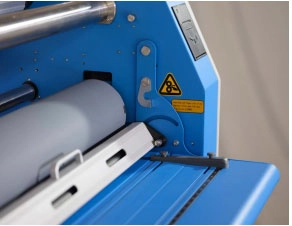

Along with its rugged design and many built-in labor-saving features, the 663TH's electric servo motor and positioning encoder deliver precise control of roller gap position and nip pressure. A host of production class features like integrate rear rewind, inline slitting, and swingout shafts provide the reliable performance the finishing professionals need to ensure the highest quality output and maximum productivity.

INTEGRATED REAR REWIND

is motorized for longer,

uninterrupted roll-to-roll operation.

THREE SWINGOUT SHAFTS

save time loading and unloading rolls

for faster setup and change-overs

TOP HEAT ASSIST

softens film adhesive to reduce

silvering for better quality output

and to shorten processing time.

ROLL LABEL PRINTER

generates pressure sensitive label with

film description and remaining footage

for labeling partial film rolls.

Click the link below to see this feature in action

Graphic Finishing Products 663TH

Specifications